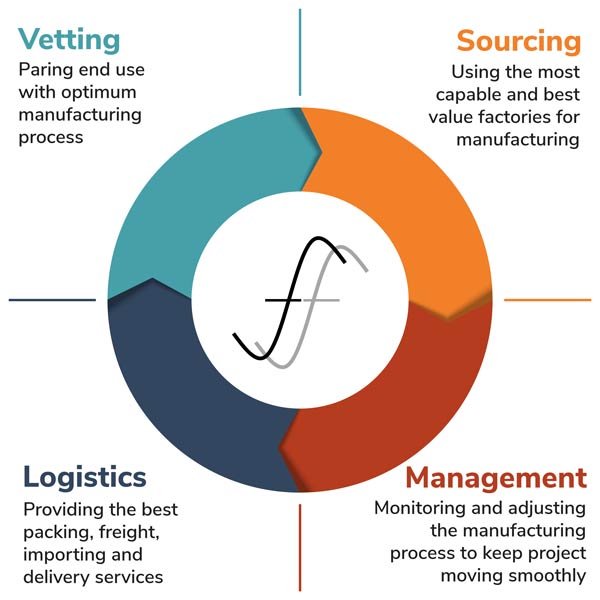

End results require close monitoring of production manufacturing. Freyr remains involved during production to proactively address issues that could yield compromised finished product. Keeping a close eye as things progress and communicating potential issues keeps projects on schedule, on budget and enhances quality control.

Freyr has developed customized software with MOXO to create a seamless interface with all parties involved with the project through a proprietary client interaction workflow. You will work through a dashboard specific to each project to share documents, participate in interactive meetings, share scheduling updates, etc. No more going through different channels to check on things as the project advances. Track manufacturing progress or monitor the real time location of a container shipment without waiting for someone to get back to you. It is your information at your fingertips, accessible at any time.